Tel/WhatsApp

Tel/WhatsApp

Doing Holdings Co., Ltd

Doing Holdings Co., Ltd

(1) Purpose of edible oil refinery plant: Oil refining machine, according to the different usage and requirements, utilizes the physical and chemical methods to get rid of the harmful impurities and needless substance in the crude oil and then gets standard oil.

Our edible oil refinery plant is suitable for refining various crude vegetable oil, such as sunflower seed oil, tea seed oil,

groundnut oil, cottonseed oil, palm oil, rice bran oil, soybean oil, corn oil and palm oil, etc.

(2) Main parts of edible oil refinery plant: refining pot, decoloration pot, deodorization pot, oil pumps and other parts.

(3) Advantages of edible oil refinery plant:

a .After refining, the impurity of oil must be less than 0.2% ;

b.Recycling system save power and money ;

c.Lower oil waste.

Edible oil refinery plant

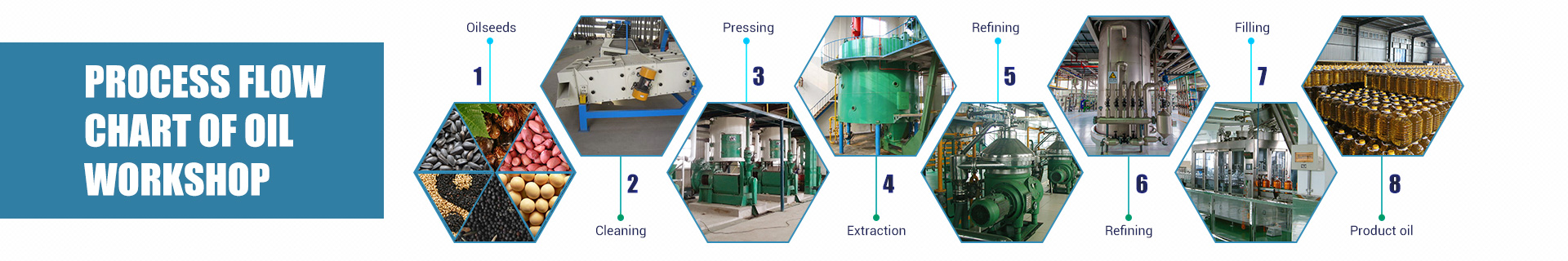

2.Working process of edible oil refinery plant :

(1)Pump crude oil into refining tank and heat with conduction oil, and the temperature will reach about 70°C-80°C after one hour.

Add acid or alkali to separate according to the acid value. After one hour's processing and 4-6hours deposit, then convey soap stock to storage tank.

(2)Pump refined oil into decoloring tank. When it is up to 90-110°C after one hour's heating, add clay into tank for 20min's processing. Then separate clay and oil with filter.

(3)Put discolored oil into deodorization tank with vacuum pump. Heat and process with steam for odor removal. After filtering, you will get final oil product.

3.Functions of main parts of edible oil refinery plant :

(1) Refining section: used to P-acid de-gumming, alkali refining de-acid and water rinsing.

(2) Decoloring section: used to remove off pigments, bleaching oils and grease dehydrate.

(3) Deodorizing section: to remove off the odor components in oil.

(4) Dewax: used to remove off the wax in the oil, in order to get the high quality oil.

(5) Heat-transfer oil stove: supply each device production needing heat energy, temperature reach above 280°C.

(6) Steam generator: produce the needing steam for de-odoring and distillation.

(7) Vacuum pump: supply needing vacuum for dehydrate, de-color, de-odor. Vacuum degree can reach above 755mm Hg.

(8) Press filter: filter clay, filter out clear oil.

(9) Air compressor: blow dry bleached clay, blow empty the leftover oil in the press filter.

If you wanna to get more details about Edible oil refinery plant you can send E-mail to market@doinggroup.com. You can consult our professional engineer and specialized sales team with leave a message in below form.We will contact with you ASAP.You also can visit our factory in Henan,China.