Tel/WhatsApp

Tel/WhatsApp

Doing Holdings Co., Ltd

Oil mill plant

We are a large oil engineering company of designing, manufacturing, installation, commissioning and after-sale services of oil mill plant. We have 100% of turnkey engineering ability of the whole oil mill plant from pretreatment, pressing, leaching, refining to packing. Oil crops like rapeseed, sunflower seeds, cottonseed and soybean can be pressed with our oil mill machinery to obtain high-quality edible oil.

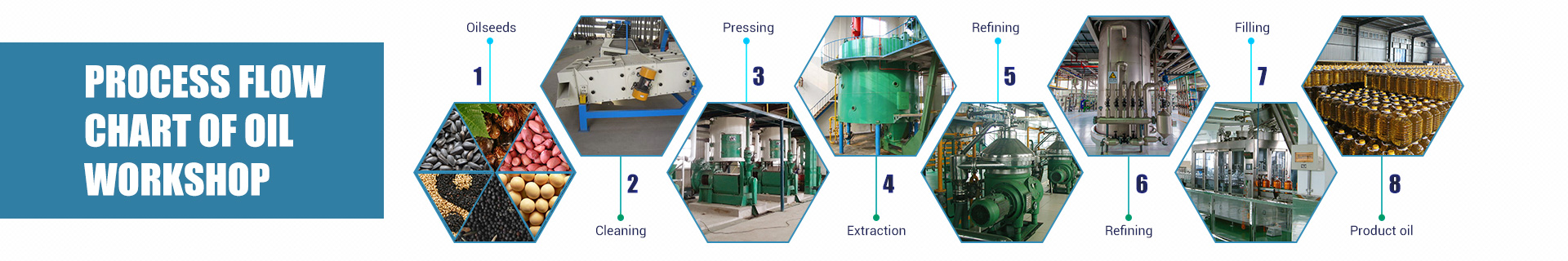

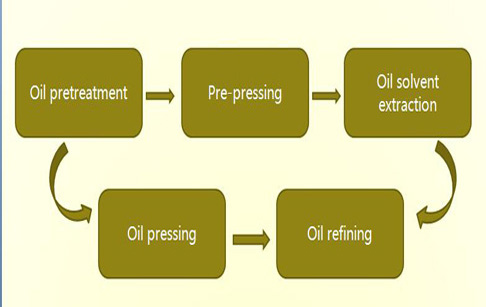

Oil mill plant process:

Oil mill plant process

Oil seed pretreatment - oil mill plant:

Pretreatment of material is an important process in oil processing. The purpose of pretreatment is to improve the appearance of oil plants to make the pressing and leaching process more rapid and efficient. It includes the following series of process: drying, color sorting, crushing, softening, peeling, extrusion, flaking, steaming and frying, pressing, etc.

Our pretreatment technology and equipment is suitable for processing various oil plants, and unique design and manufacturing can be realized according to the actual situation, different oil plants and requirements of our clients to improve oil quality and ensure the smooth operation of subsequent sections. Adopt the most advanced automatic control system and the central computer control system. Network technology is applied for remote monitoring and maintenance of principal machines to achieve electromechanical integration and automation, and make the whole oil mill plant energy conservation and environmental protection.

Scope of application of oil mill plant :

The pretreatment of soybean, rapeseed, cottonseed, sunflower seeds, peanut, corn germ, rice bran, safflower seed, tea seed, sesame seed, palm, walnut and other oil plants.

Cooking oil pretreatment machine

Oil pressing - oil mill plant

At present, oil mill plant is widely used in continuous mechanical oil extraction with the pressing capacity of 1 - 1000 TPD. Prepressing (combination with solvent extraction) and full pressing (purely mechanical oil extraction process) are the two main pressing methods used in oil mill plant for oil extraction. Prepressing and full pressing have their own features and advantages when pressing oil plants.

Oil pressing machine

Prepressing- Oil mill plant

In prepressing technology, oil plants are pressed lightly without the application of full pressure. The residual oil content in the prepressed cake is about 13%-17%. Then, the pre-pressed cake would be sent to the solvent extraction plant. We provide pre-pressing machines manufactured in accordance with global standards for oil mill plant with advantages of easy operation, convenient maintenance and cost-effective.

Full Pressing- Oil mill plant

The full or single pressing technology is used in oil mill plants of small and medium capacity. In full pressing process, oil plants are pressed in single step under the principle of mechanical extraction to separate oil from seeds. As a result, maximum oil yield can be obtained from high oil content plants. The residue oil in the pressed cake is only about 4-6%. Full pressing technology can be used for processing different oil plants. The full pressing oil mill plant produced by our company has superior quality and higher yield.

Generally speaking, the oil yield of mechanical pressing is only 65-70%. Thus, prepressing of oil plants is often used to extract 60 to 70% of the oil, while the residual oil is extracted by solvent.

Cooking oil solvent extraction - oil mill plant

Generally, for oil plants with high oil content, such as rapeseed, sunflower seed and peanut kernels, prepressing - solvent extraction process is often used for oil extraction. For oil plants with low oil content like soybean and rice bran, they can be processed with direct solvent extraction process.

Oil solvent extraction

Oil refinery-oil mill plant

Oil refining mainly refers to the purification of unrefined oil. Impurities in the unrefined oil would not only affect the edible value and oil storage, but bring difficulty for further processing. Therefore, the purpose of the oil refining is to remove the undesired and harmful impurities from oil according to different requirements and uses to get refined oil products that can meet the quality standard. The oil can be refined by chemical or physical refining process according to the types and qualities of the oil to be processed. The process of oil refining includes degumming, neutralization, bleaching, deodorization and winterization. Chemical Refining is the most widely used process for vegetable oils, especially seed oils like soybean oil, canola oil, corn oil, cottonseed oil, sunflower oil, safflower oil, etc.

Oil refinery plant

With scientific management, excellent manufacturing process and innovative manufacturing idea, our company has grown into the oil machinery production and export base in China. We have built more than 200 oil mill plants at home and abroad and over 6000 units of small oil mill (or corollary equipment) so far. Our oil mill machinery sells well all over the country and has been exported to more than 30 countries and regions, such as Russia, India, South Africa, Ukraine, Nepal and Indonesia.

If you are interested in oil mill plant and want to start a cooking oil mill plant business.weclome to contact us when you are free,and our engineer will give you a professional and feasibility program with the low cost.

If you wanna to get more details about Oil mill plant you can send E-mail to market@doinggroup.com. You can consult our professional engineer and specialized sales team with leave a message in below form.We will contact with you ASAP.You also can visit our factory in Henan,China.