Tel/WhatsApp

Tel/WhatsApp

Doing Holdings Co., Ltd

Doing Holdings Co., Ltd

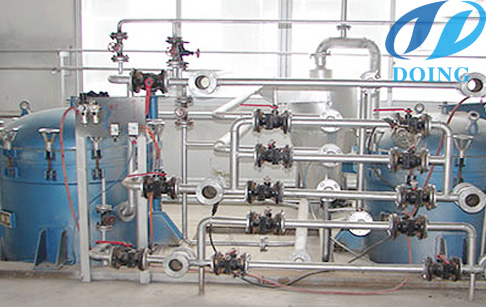

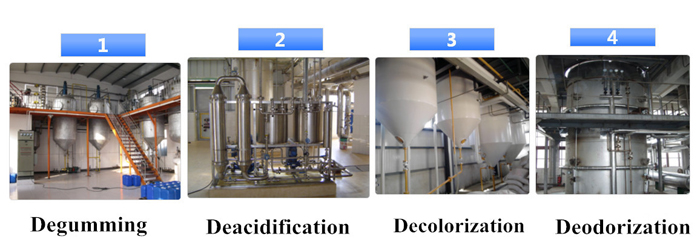

Physical refining is the way that the crude oil after pretreatment, degumming, bleaching, in heating and high vacuum conditions, by means of direct steam distillation principle, process the oil than three ester relative volatility much lower free fatty acids and low molecular odor substances discharged together with the steam, it also can be called "the sour water stripper" or "distillation acid". Physical refining process also has batch, semi continuous and continuous type. The whole refining process includes crude oil pretreatment (filter), degumming, washing, bleaching and degassing - distillation step acid etc.

Cooking oil refining machine

Operating Requirements:

1. Before deacidification feedstock pretreatment requirements: strict degumming and deacidification indicators: residual phosphorus at 10 × 10-6; metal ions at 1 × 10-6; residual soap, clay for trace; acid value the range below 14;

2. Deacidification oil 220-275 ℃;

3. Vacuum, high vacuum, help to reduce the stripping resistance, reduce the oil temperature, reducing steam consumption and improving oil spray. General range: cannibalism pressure gas 0.133-0.665kPa (1-5mmHg), usually 0.133-0.4kPa (1-3mmHg).

4. Deacidification time, and the oil content and fatty acid removal indicators related to the general requirements and deodorization same as 45-100min (intermittent operation time a bit longer, about 150min).

Cooking oil refining machine

Application features:

1. The use deacidification tower can directly remove FFA, it significantly reduced the loss of neutral oil, and can be as low as 1.05- 1.1%, while the loss of the base oil refining is higher than 1.4%;

2. Deacidification and deodorization available with complete set of equipment, saving investment;

3. Generally suitable for bottom of glioma in oils, such as olive oil, palm oil, palm kernel oil, peanut oil, and sunflower oil, but for high phosphorus content and difficult threshing soybean oil, Rapeseed Oil also exist, such as finish color reversion of the problems to be solved;

4. Crude oil pretreatment higher production costs, partially offset by the advantages in the sense yield of neutral oil.

Cooking oil refining machine

Process and operating conditions:

1. The raw oil degumming works best, residual phosphorus content must be compliance;

2. The optimum temperature range 220-250 ℃, in order to avoid changing the molecular structure of the oil at high temperatures caused by the recollection, color reversion phenomenon;

3. The device to prevent leaks, high vacuum system requirements, residual pressure 133.32-266.64Pa;

4. The amount of stripping steam at 240 ℃,133.32Pa conditions 40-50kg / t oil;

5. The heating medium conducting oil (oil temperature 280-320 ℃) or high-pressure steam (pressure 6-8MPa);

6. Each layer tower oil level 300-450mm;

7. Sufficient residence time, total time stripping off acid 60-100min.

If you want to get more information about the cooking oil refining process ,weclome to contact us, and our engineer will give you a feasibility program according to your requirement.

If you wanna to get more details about Physical refining in cooking oil refining process you can send E-mail to market@doinggroup.com. You can consult our professional engineer and specialized sales team with leave a message in below form.We will contact with you ASAP.You also can visit our factory in Henan,China.