Tel/WhatsApp

Tel/WhatsApp

Doing Holdings Co., Ltd

Doing Holdings Co., Ltd

Our company is professional in sunflower oil plant design, installation, trial run, technical trainning and so on. We can provide you the turn key project of the whole sunflower oil plant from10 to 2000TPD .

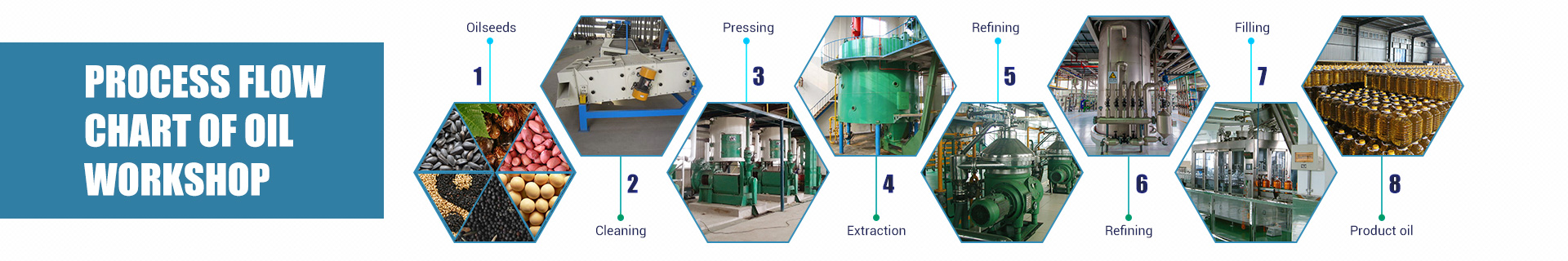

Sunflower oil has high nutritive value, it contains about 90% unsaturated fatty acids,and the essential fatty acidlinoleic acid accounts for about 66%. In order to improve oil yielding rate and get high quality sunflower oil, the sunflower oil plant should consist of following processes: pretreatment, prepressing, extracting and refining.

Pretreatment section of sunflower oil plant

Here is an brief introduction of sunflower oil plant:

Ⅰ Pretreatment section of the sunflower oil plant

Pretreatment section is to remove the impurities in the raw material and change its structural characteristics to make it accordance with requirments of different oil producing process.

Raw material

↓

Magnitic seperating→ Metal impurities

↓

Cleaning→Other impurities

↓

Husking→Sunflower seed hull

↓

Cooking

↓

Prepressing→Crude oil

↓

Sunflower seed cake→ Extracting Workshop

Sunflower oil plant

1>Magnitic seperating:In order to remove the metal impurities, so that can prevent damaging the equipment and occuring safety accidents.

2>Cleaning: To remove the impurities in the raw matrial such as soil, stem and leaf, hull and moldy seeds.

3>Husking: In order to improve the oil yielding rate and the quality of crude oil and meal, reduce the wear to the equipment, the hull must be removed.

4>Flaking: To damage the oil cell, increase the surface of oilseeds, shorten the oil outflowing distance, in this way, it is beneficial to extract the oil and improve the cooking effect.

5>Cooking: This processing can improve prepressing oil yielding rate and the quality of the cake, adjust the moisture, temperature and plasticity of the flake.

6>Prepressing: To squeeze out part of the oil in the raw material, and improve extracting effect.

Sunflower oil plant for solvent extraction

Ⅱ Extracting section of the sunflower oil plant

Extracting section is to extract the oil by suitable organic solvent, this method can get the highest oil yielding rate.

Fresh Solvent

↓

Cake → Extracting→Wet Meal→Desolventising → Meal

↓

Miscella ↓

↓

Evaporating and stripping→ Solvent mixture →Condensing and Recovering

↓ ↓

Crude Oil Solvent Recycling

↓

Refining Workshop

1>Extracting:To extract the oil in the cake by solvent, the general solvent is 6# extraction solvent oil or commercial hexane.

2>Desolventising: To remove and recover the solvent in the meal; Dry and cool down the meal at the same time.

3>Evaporating and stripping: Heating the the miscella by indirect steam, so that can vaporize the solvent and concentrate the miscella.

4>Solvent recycling: This process is to recover the solvent, decrease solvent comsuption, keep safety prodution and improve product quality.

Ⅲ Refining section of the sunflower oil plant

Refining section is to remove the impurities in the crude oil and improve oil quality.

Crude Oil

↓

Hot water→Degumming→ Oil Foot

↓

Alkali liquor→ Deacidfying → Soap Stock

↓

Activeted Clay→Decoloring → Waste Clay

↓

Deodorizing

↓

Dewaxing →Wax

↓

Refined Oil

Sunflower oil plant

1>Degumming:To remove the gum impurities, and prepare for the subsequent refining processes.

2>Deacidfying:To remove the free fatty acid in the crude oil.

3>Decoloring: To remove the pigment in the crude oil by adding active clay, so that can improve the oil quality.

4>Deodorizing:To remove the odor in the oil, so that can improve the flavor, stability, color and quality of the oil.

5>Dewaxing: To renmove the wax in the oil and improve the quality of the oil.

Welcome to consult our sunflower oil plant.

If you wanna to get more details about Sunflower oil plant you can send E-mail to market@doinggroup.com. You can consult our professional engineer and specialized sales team with leave a message in below form.We will contact with you ASAP.You also can visit our factory in Henan,China.