Tel/WhatsApp

Tel/WhatsApp

What is plastic and tyre Pyrolysis?

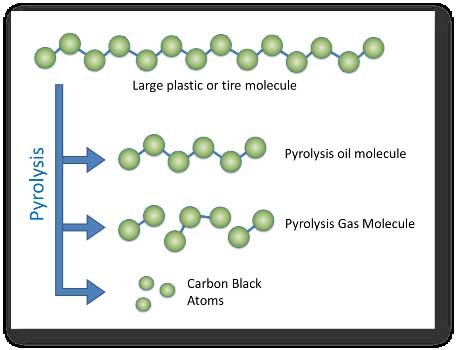

Plastic and tyre pyrolysis involves subjecting plastic and tire rubber to high temperature of 400 to 450 degree Celsius, in absence of oxygen. In case of oxygen is present plastic will start burning. During pyrolysis plastic and tire breaks down into smaller molecules of pyrolysis oil, pyrolysis gas and carbon black. Like plastic and tire rubber , pyrolysis end products are also hydrocarbons. Pyrolysis is great way of recycling waste plastics and tires rubbers. Given below are benefits of waste plastic and tyre pyrolysis.

Fully automatic continuous tyre/plastic pyrolysis machine

Fully automatic continuous automatic tyre/ plastic pyrolysis machine is a significant improvement based on the existing intermittent pyrolysis plant at home and abroad, continuous automatic tyre/ plastic pyrolysis machine fully realize the automatic operation ,continuous automatic tyre/ plastic pyrolysis machine,Reactor than the intermittent pyrolysis plant can prolong life 5-6 years.

Fully automatic continuous tyre/plastic pyrolysis machine include Fully automatic continuous tyre/plastic pyrolysis machine

Fully continuous pyrolysis plant

The whole fully automatic continuous tyre/plastic pyrolysis machine composite by 13 parts, those are reactor ,driving device ,vertical catalytic chamber, vertical condenser, oil and water separator, horizontal condenser ,heavy oil tank ,light oil tank , anti-back fire device, vacuum system , dedusting device, draft fan, chimney.

Reactor is one of the most important parts. The material and welding technology of reactor will have a direct impact on safety and durable life. In order to guarantee the quality of reactor, we use auto welder .The welding seam will get X-ray detection and heating treatment.

Condensers adopt water cooling way and the inner cooling tube are made of seamless steel pipe ,the diameter is 48mm.the heat exchanging area is about 13 square meter ,the total heat exchanging area is 40 square meter to get the best temperature for oil gas liquefied.

Fully automatic continuous tyre/plastic pyrolysis machine final product application

Fuel oil (40% to 45%)

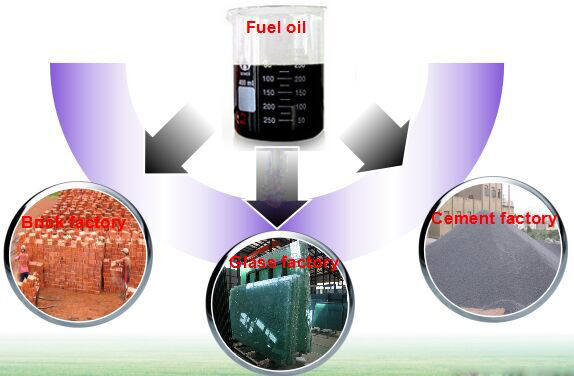

Fuel oil application

The main oil product produced by our recycling application is the fuel oil that is wide used for industrial and commercial purposes. The oil has 40% to 45% of the amount of recycled scrap tyres, which will be carried with licensed tanker trucks.

Carbon black (30% to 35%)

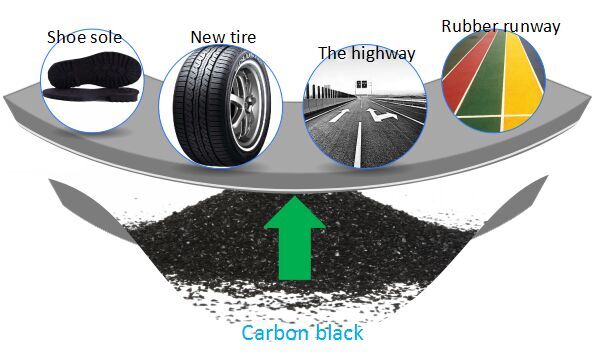

Carbon black application

Carbon Black is the main product recycled by Pyrolysis technology. The amount of recycled carbon black is 30% to 35% (depending on the type of tyres) of the total amount of scrap tyres recycled in the system. Carbon black is used as raw material or main ingredient in many industries and the chemical structure of carbon black strengthens, lengthens the endurance, and improves the coloring features of the materials.

Carbon black produced by Pyrolysis process (CBp) is more economical compared to carbon black produced primarily from petroleum and is more price-efficient to be used as an ingredient in the industries listed;

* Electric cable jacketing

* Conveyor band

* Carrier Bands

* Hose and doormat

* Black nylon bag

* Rubber additive

* Automotive spare parts

* Heat isolation

* Black colorant in rubber materials

* Plastic pipes

* Industrial rubber products

* Fire fighting

Stell wire (10% to 15%)

Tyres contain steel wires and the amount range of 10% to 15% of the total tyre wastage. All of the steel present in the tyre can be detached after pyrolysis recycling process in completed. Valuable steel wires are pressed and sold to steel and scrap dealers.

GAS (10% to 12%)

Non-Condensable gases arise during the pyrolysis process.

Some advantages such as…..

* It has higher calorific value as compared to Natural Gas.

* It can be replaced where Natural Gas and Propane are stored.

* The high energy gas may be utilized as a source of energy for the Pyrolysis process.

* The amount of gas generated in the system is 12% to 15% of the total amount of recycled tyres and considering the 10 ton scrap tyre/day recycling capacity, the facility generates 1200-1500 m3/day gas, which has an enormous energy potential when evaluated.

For more information about Fully automatic continuous tyre/plastic pyrolysis machine please kindly leave your requirments and your contact information. Our professional project manager will contact you within 24 hours.