Tel/WhatsApp

Tel/WhatsApp

Continuous waste tires pyrolysis machine is an effective and environmental recycling solution for waste management. Due to the waste tires are difficult to decompose within a short time, waste tires pollution has become a big problem in our surroundings. To address this issue, some effective recycling solutions emerged such as waste tires pyrolysis machine. Among these pyrolysis machine manufacturer and suppliers, DOING has been involved in researching and manufacturing pyrolysis machine for over 14 years and has abundant successful project experience. And now one of DOING popular pyrolysis machines is the continuous waste tires pyrolysis machine, which gained lots of good feedback due to its larger processing capacity and higher work efficiency.

DOING continuous waste tires pyrolysis machine for sale

DOING continuous waste tires pyrolysis machine for sale

DOING continuous waste tires pyrolysis machine uses the most advanced pyrolysis technology combining with our own experience, which can recycle various type of waste tires and rubber to fuel oil, carbon black and syn-gas. And for our continuous waste tires pyrolysis machine, we have two types: semi-continuous design and fully continuous design, which have different advantages to meet your various demands:

| Semi-continuous design | Fully continuous design | |

| Feeding material | Rubber power(16-18mesh) | |

| Feeding method | Automatic feeding | |

| Discharging method | High temperature discharging | |

| Processing efficiency | 3 batch in 2 days | Continuous processing for about 45 days |

How to feed waste tires or rubber into continuous waste tires pyrolysis reactor?

Generally, the waste tires will be fed into semi-continuous/fully continuous waste tires pyrolysis reactor by using an automatic screw feeder. To ensure the continuous feeding and discharging of the continuous waste tires pyrolysis machine, before feeding, we need to process the waste tires into rubber pieces between 16 and 18 mesh. Here DOING also provides rubber powder production line to help you.

Pretreatment for continuous waste tires pyrolysis machine

Pretreatment for continuous waste tires pyrolysis machine

Technical parameter of DOING continuous waste tires pyrolysis machine for sale

| Item | Specifications | |||||

| Model | DY-C-10 | DY-C-15 | DY-C-20 | DY-C-30 | DY-C-40 | DY-C-50 |

| Capacity | 10T/D | 15T/D | 20T/D | 30T/D | 40T/D | 50T/D |

| Feedstock | Waste tires/plastic/rubber | |||||

| Output | Fuel oil, carbon black, syn-gas | |||||

| Thickness | 14/16/18/20mm | |||||

| Heating type | Indirect heating | |||||

| Required workers | 1-2 workers per shift | |||||

| Heating fuel | Fuel oil, natural gas, coal, wood | |||||

| Reactor materials | Q345R(304ss/316ss/309ss/310ss material could be customized) | |||||

| Cooling type | Circulating water cooling | |||||

| Cooling system | Shell tube condensation system | |||||

| Land occupy size | Take 50TPD machine as an example, it's about 700 m2 | |||||

Why choose DOING continuous waste tires pyrolysis machine?

1. Security:

a. Adopting auto-welding technology

b. All of the welding will be detected by our professional welders in factory who are skilled in the auto-welding to ensure the welding quality and the welding shape.

Manufacturing of DOING continuous waste tires pyrolysis machine

Manufacturing of DOING continuous waste tires pyrolysis machine

c. Adopting process controlling system control the quality, every manufacture process, manufacture date, etc.

d. Equipped with safety valves, emergency valves, pressure and temperature meters, as well as the alarming system.

2. Environmental-friendly:

a. Emission Standard: equipped with full set of environmental protection system to meet the emission standards in various countries.

b. No gas pollution: fully enclosed during the operation and equipped with the tail-gas cleaning system and desulfurization tower to make full purifying of exhaust gas.

Environmental protection systems of DOING continuous pyrolysis machine

Environmental protection systems of DOING continuous pyrolysis machine

c. No water pollution: adopting circulating water system to avoid water pollution.

d. No noise pollution: the noisiest part of our machine is the draft fan.Its noise is less than 50dB.

3. Energy conservation and low cost on operation:

Special covers of the reactors and chambers can keep hot during the heating in good efficiency as well as the direct heating system to save energy and cost. Also the purified tail gas will be transported to heat the pyrolysis reactor directly to save operation cost.

Syn-gas recycling of DOING continuous waste tires pyrolysis machine

Syn-gas recycling of DOING continuous waste tires pyrolysis machine

4. High work automation and large processing capacity

For continuous waste tires pyrolysis machine, DOING has the processing capacity 15/20/30/40/50TPD, which provides large processing capacity to meet the demands of customers. Also our continuous waste tires pyrolysis machine is equipped with the fully automatic PLC control system to realize continuous production for over 45 days without stopping.

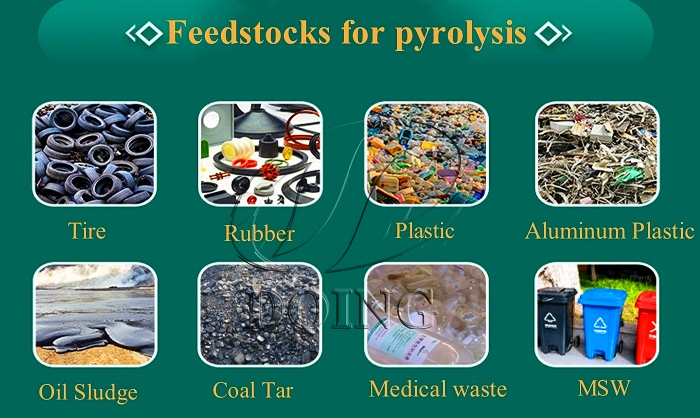

The raw material of continuous waste tires pyrolysis machine:

Raw materials suitable for continuous waste tires pyrolysis machine

Raw materials suitable for continuous waste tires pyrolysis machine

The end product of continuous waste tires pyrolysis machine:

| Name | Usage |

| Fuel oil | *can be sell directly. *can be make diesel and gasoline by using waste oil distillation machine. *can be as fuel in heavy oil machinery, such as cement plant, steel plant, glass plant, brick plant, etc. |

| Carbon black | *can be sell directly. *can be made fine carbon by using carbon refining machine. *can be made carbon pellet by using pellet machine. |

| Syn-gas | *can be as fuel heating pyrolysis machine. *can be storage as fuel for other heating. |

For over past 14 years, DOING has cooperated with many customers on our continuous waste tires pyrolysis machines in various countries, such as Brazil, India, America, Thailand, Vietnam, Malaysia, Iraq, Russia, China, Sri Lanka, Kazakhstan, etc. So DOING can provide professional and comprehensive services for you to help you set up the project if you are interested in our continuous waste tires pyrolysis machines.

DOING continuous waste tires pyrolysis machines projects

DOING continuous waste tires pyrolysis machines projects

For more information, just feel free to contact us directly!

For more information about Continuous waste tires pyrolysis machine please kindly leave your requirments and your contact information. Our professional project manager will contact you within 24 hours.