Tel/WhatsApp

Tel/WhatsApp

Tyre recycling process pyrolysis plant introduction

Pyrolysis technology is regarded as the most advanced method on waste tyre disposal, owing to it is a new green and economic solution on waste tyres within a sealing high-temperature reactor. Our tyre recycling process pyrolysis plant adopt the advanced pyrolysis technology that can convert waste tyre to fuel oil, carbon black and steel wire.

Tyre recycling process pyrolysis plant

Tyre recycling process pyrolysis plant

Status of waste tyre raw material

With the rapid development of the world automobile industry and transportation industry, the demand of various tyre is increasing day by day, at the same time, the used tyres are produced accordingly and its number is also growing largely. As we know waste tyre is a kind of non - fusible or refractory polymer elastomer material. It needs hundreds of years for the large molecules decompose to be no affect to normal growth of plant in the earth. More and more waste tyres not only takes up quantities of farmland, but also breeding ground for insect - borne diseases (dengue fever etc), sharply deteriorated natural environment, destroyed vegetation, endangers environment seriously.Besides, it may cause fire and threaten people's life and the property security. It is called "black pollution". So waste tyre recycling is becoming more and more important and urgent.

Raw material suitable for tyre recycling process pyrolysis plant

1. Waste tyre/tire

2. Waste plastic

3. Waste rubbber

2. Waste oil sludge

Raw material suitable for tyre recycling process pyrolysis plant

Raw material suitable for tyre recycling process pyrolysis plant

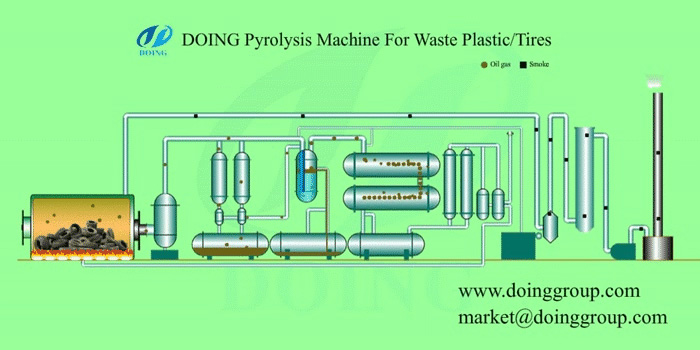

Tyre recycling process pyrolysis plant main parts

As shown in the picture below, the tyre recycling process pyrolysis plant mainly consists of the following components.

Auto-feeder

| To shorten feeding time; Can save workers,save time and save energy. |

Pyrolysis reactor

| Q245R/Q345R materials pyrolyze waste tire/plastic/rubber in here |

Buffer chamber

| To reduce oil gas speed and improve oil quality. |

Oil-water separator

| Avoid oil gas reback to pyrolysis reactor and ensure running safety. |

Cooling system

| (Vertical condensers and horizontal condensers) better condensing effect to get more oil. |

Oil tanks

| Collect tire/plastic oil. |

Negative pressure device

| Guarantee machine working under normal pressure safety; Shorten pyrolysis time. |

Dust removal system

| Ensure the smoke emission reach international standard. |

Bad smell removal system

| Remove bad smell and keep a well environmental working place; Ensure smell emission reach international emission standard. |

Carbon black slagging device

| Slagging carbon black automatically; Environmental protection; Save time and manpower. |

Tire pyrolysis process in tyre recycling process pyrolysis plant

1. Feeding

Feed raw material (waste tyre) into pyrolysis reactor by auto-feeder. The reactor is supposed to be left 1/3 space for rotating more smoothly. Then make sure the door of pyrolysis reactor is closed.

2. Pyrolysis

Pyrolysis reactor will be gently heated by burning the fuel material (coal, wood, natural gas, LPG or tire oil generated from last batch). The water vapor in raw material will be released when the temperature reached 100℃.Oil gas(including heavy oil gas, lighter oil gas and incondensable gas)will be generated gradually in the pyrolysis reactor with heating. 250-280℃ is the top output rate interval.

3. Cooling

Heavy oil gas separated by manifold is supposed to be liquefied and drop down into the heavy oil tank. The lighter oil gas will rise up to the cooling system then be cooled into liqued oil and stored in the oil tank. The incondensable gas though dusulphurization and dedust by hydroseal will be led to the furnace for recycling.

4. Slagging

After all fuel oil is produced, the reactor should be cool down. Carbon black will be discharged automatically when the temperature falls down 40 degree. If the raw material is the whole tire, please take out steel wire form the reactor by hooks below 50 Celsius at least.

Flow chart of tyre recycling process pyrolysis plant

Flow chart of tyre recycling process pyrolysis plant

Tyre recycling process pyrolysis plant technical parameters

| No. | Items | Contents | ||

| 1 | Equipment type | DY-1-6 | DY-1-10 | DY-1-12 |

| 2 | Raw material | Waste tire | Waste tire | Waste tire |

| 3 | Structural form | Horizontal rotation | Horizontal rotation | Horizontal rotation |

| 4 | 24-hour Capacity | 6 ton | 10 ton | 12 ton |

| 5 | Oil yield | 2.7-3.3ton | 4.5 -5.5ton | 4.8 -6.6ton |

| 6 | Operating pressure | Normal | Normal | Normal |

| 7 | Material of pyrolysis Reactor | Q245R | Q245R | Q245R |

| 8 | Thickness of pyrolysis Reactor | 16mm | 16mm | 16mm |

| 9 | Rotate speed of pyrolysis Reactor | 0.4turn/minute | 0.4turn/minute | 0.4turn/minute |

| 10 | Total power | 15KW | 15KW | 15KW |

| 11 | Mode of cooling | Water cooling | Water cooling | Water cooling |

| 12 | Cooling area of condenser | 100sqm | 100sqm | 100sqm |

| 13 | Kind of transmission | Internal gear drive | Internal gear drive | Internal gear drive |

| 14 | Noise dB(A) | ≤85 | ≤85 | ≤85 |

| 15 | Size of Reactor(D×L) | 2200×6000 | 2600×6600 | 2800×6600 |

| 16 | Working form | Intermittent operation | Intermittent operation | Intermittent operation |

| 17 | Delivery time | 20days | 20days | 20days |

| 18 | Weight | 27T | 32T | 35T |

Unique advantages of tyre recycling process pyrolysis plant

1. Security

a. Adopting automatic submerged-arc welding technology and all of the welding will be detected by the ultrasonic nondestructive testing method to ensure the welding quality and the welding shape.

b. Adopting process controlling system control the quality, every manufacture process, manufacture date, etc.

c. Equipped with anti-explosion device, safety valves, emergency valves, pressure and temperature meters, as well as the alarming system.

2. Environmental-friendly

a. Emission Standard: Adopting special gas scrubbers to remove acid gas and dust from smoke.

b. Smell during operation: the tyre recycling process pyrolysis plant is fully enclosed during the operation, and no overflow.

c. Water pollution: We use circulating cooling water, which is not in direct contact with oil gas and will not cause pollution.d. Solid pollution: the solid after pyrolysis is the crude carbon black and steel wires which can be deep-processed or sold directly with its value.

3. High oil yield

a. We provide professional workers training, equipment operation and temperature control very in place which can improve the rate of oil output of raw materials;

b. Our condensing equipment adopts three-stage condensation, which has better cooling effect and can improve oil yield.

Tyre recycling process pyrolysis plant project cases

Now, our products have sold well in more than 60 countries and regions around the world, winning great praise and trust of our customers all over the world!

Tyre recycling process pyrolysis plant project cases in some countries

Tyre recycling process pyrolysis plant project cases in some countries

Tyre recycling process pyrolysis plant final product and their applications

| NO | Name | Percentage | Usage |

| 1 | Fuel oil | 45% | 1.Can be sold directly; 2.Can be as fuel; 3.Can be used industrial and commercial purposes. |

| 2 | Carbon black | 30% | 1. Can be sold directly; 2. Can be used electric cable jacketing,black nylon bag, rubber additive |

| 3 | Steel wire | 15% | 1. Can be sold directly; 2.Make steel bloom by use hydraulic press-packing. |

| 4 | Oil gas | 10% | 1. Can be as fuel burn by use gas burning system; 2. Extra gas also be storage as fuel for other heating. |

Our company

We are professional manufacturer of tyre recycling process pyrolysis plant for nearly 10 years. We provide on-site installation service for engineers, and we can help customers train workers to operate pyrolysis plant. We have a team of professional designers who can customize the equipment according to your specific needs. We sincerely look forward to cooperating with you.

For more information about Tyre recycling process pyrolysis plant please kindly leave your requirments and your contact information. Our professional project manager will contact you within 24 hours.