Tel/WhatsApp

Tel/WhatsApp

DOING waste plastic pyrolysis plant is an environmental protection system which adopt the pyrolysis technology and catalytic breakdown reaction to convert waste plastics into renewable resources, such as pyrolysis oil, carbon black, combustible gas and so on. The obtained pyrolysis oil can be used in boiler and generators directly as fuel, or come into high ranking diesel by our pyrolysis oil distillation plant. Other names of waste plastic pyrolysis plant include waste plastic pyrolysis machine, waste plastic recycling plant, plastic to oil machine, plastic to fuel conversion plant, plastic to oil conversion machine and so on.

DOING waste plastic pyrolysis plant

DOING waste plastic pyrolysis plant

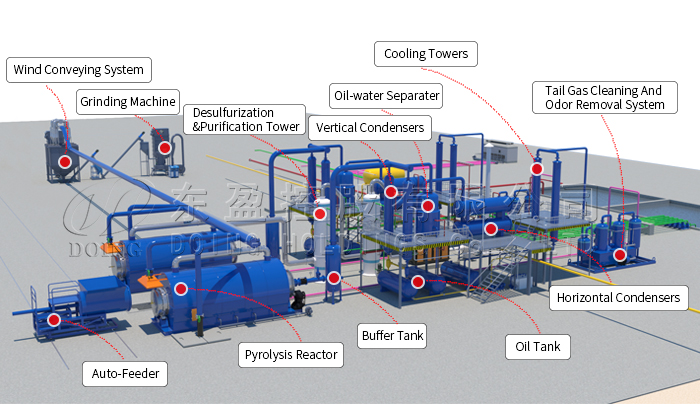

Main components of waste plastic pyrolysis plant

Doing Group's waste plastic pyrolysis plant mainly includes pyrolysis reactor, oil and gas separator, vertical/horizontal condenser, water seal, vacuum device, oil tank, dust removal and deodorization device, control cabinet, heating furnace, etc.

Main components of waste plastic pyrolysis plant

Main components of waste plastic pyrolysis plant

Environmental protection configuration

In order to meet the stringent environmental assessment standards in Europe and the United States and other countries, Doing Group has adopted the concept of exhaust gas and waste water recycling as far as possible to achieve zero emissions. Through water seals, oil-water separators, tail gas deodorization device and desulfurization & purification tower, the separation of water, oil gas, and waste slag can be achieved, whereby oil gas are recovered, waste generated is recycled, and the entire production process is environmentally friendly.

Main environmental protection configurations of waste plastic pyrolysis plant

Main environmental protection configurations of waste plastic pyrolysis plant

Raw material and oil yield in DOING waste plastic pyrolysis plant

| Raw material | Picture | Oil Yield |

| Pure PE |  | 50%-95% |

| Pure PP |  | 50%-90% |

| Pure PS |  | 75%-90% |

| Pure ABS |  | 40% |

| Pure Plastic cable |  | 80% |

| Plastic bag |  | 50% |

| PVC |  | Not available |

| PET |  | Not available |

The main working process of waste plastic pyrolysis plant

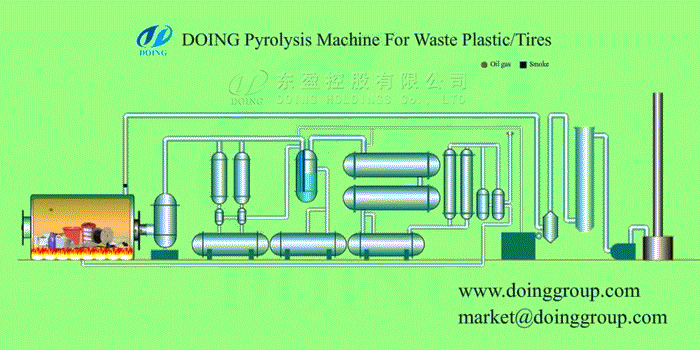

1. Put raw material into pyrolysis reactor by an automatic pusher. If your waste plastics is wet, you should dry first. This way can save operation time. The pyrolysis reactor is supposed to be left 1/3 space for rotating more smoothly. Then make sure the door of feed port is closed.

2. Heat pyrolysis reactor gently by burning the fuel material (coal, wood, natural gas, LPG or plastic oil generated from last batch can be choosed). The oil gas will be released when the temperature reached 160℃ (The most oil is produced at 220℃-280℃).

3. The oil gas will flow into cooling system and some of them will be cooled into liquid oil in there. Then store the liquid oil into oil tank. The left incondensable gas through tail gas cleaning and odor removal and desulfurization & purification tower will be led to the heating furnace for recycling.

4. After all the above work has been done, cool down the reactor. Then discharge the carbon black by carbon black discharge device.When all the work has been done, you can start the next batch.

Main working process of waste plastic pyrlysis plant

Main working process of waste plastic pyrlysis plant

DOING waste plastic pyrolysis plant technical data

| Technical parameter of waste plastic pyrolysis plant | ||||

| No. | Items | Contents | ||

| 1 | Equipment type | DY-1-6 | DY-1-10 | DY-1-12 |

| 2 | Raw material | Waste plastics | Waste plastics | Waste plastics |

| 3 | Structural form | Horizontal rotation | Horizontal rotation | Horizontal rotation |

| 4 | 24-hour Capacity | 6 ton | 10 ton | 12 ton |

| 5 | Operating pressure | Normal | Normal | Normal |

| 6 | Material of pyrolysis Reactor | Q245R | Q245R | Q245R |

| 7 | Thickness of pyrolysis Reactor | 16mm | 16mm | 16mm |

| 8 | Rotate speed of pyrolysis Reactor | 0.4turn/minute | 0.4turn/minute | 0.4turn/minute |

| 9 | Total power | 19KW | 19KW | 19KW |

| 10 | Mode of cooling | Water cooling | Water cooling | Water cooling |

| 11 | Cooling area of condenser | 100sqm | 100sqm | 100sqm |

| 12 | Kind of transmission | Internal gear drive | Internal gear drive | Internal gear drive |

| 13 | Noise dB(A) | ≤85 | ≤85 | ≤85 |

| 14 | Size of Reactor(D×L) | 2200×6000 | 2600×6600 | 2800×6600 |

| 15 | Working form | Intermittent operation | Intermittent operation | Intermittent operation |

| 16 | Delivery time | 20days | 20days | 20days |

| 17 | Weight | 27T | 32T | 35T |

| Prepared by customer about waste plastic pyrolysis plant | |||

| No. | Item | Consumption | |

| 1 | Coal(for choice) | 500kg/day | |

| 2 | Wood(for choice) | 800kg/day | |

| 3 | Natural gas(for choice) | 100-150kg/day | |

| 4 | Oil(for choice) | 300-350kg/day | |

| 5 | Electricity | 244kwh/day | |

| 6 | Water(recycled) | 60? /month | |

| 7 | Total power | 19kw | |

| 8 | Land area | 35m*15m | |

Project case

Over the years, Doing Group adheres to the business philosophy of “Quality First, Credit Foremost”, providing the best pre-sales and after-sales service and the most professional technical support to our customers, controlling the product quality strictly and constantly improving the machine design and production technology. Now, our products have sold well in more than 60 countries and regions around the world, winning great praise and trust of our customers all over the world! Here are some projects of what we've installed.

Final products and their applications from waste plastic pyrolysis plant

| Final products | Picture | Yield | Application |

| Fuel oil |  | 45% | 1. Sold outward directly. |

| 2. Added into the heavy oil generator toproduce electricity. | |||

| 3. Convert into diesel pyrolysis oildistillation machine. | |||

| 4. As fuel oil to heat the pyrolysis reactor. | |||

| Carbon black |  | 40% | 1. Sold outward directly. |

| 2. Briquetting for burning. | |||

| 3. Refining to produce new tire, shoesoles and paint. | |||

| Incondensable gas |  | 15% | 1. Back to furnace for heating pyrolysis reactor. |

| 2. Stored as fuel for other heating. |

After-sale Service of DOING company

1. We will reply your inquiry at the first sight. If there are some troublesome problems beside me, the reply will get to you no more than 24 hours.

2. We will provide the general plan of the project after we agree on the details and sign the contract.

3. If you are applying for related projects, we can provide relevant materials of waste plastic pyrolysis plant.

4. We will arrange engineers for your factory to finish the installation as well as training your workers after the equipment delivered to your factory. If for some irresistible factors our engineers are unable to reach the site, we can also provide video of the installation and commissioning of the equipment.

For more information about Waste Plastic Pyrolysis Plant please kindly leave your requirments and your contact information. Our professional project manager will contact you within 24 hours.