Tel/WhatsApp

Tel/WhatsApp

The tire pyrolysis process plant is the machine that can pyrolyze waste tires, waste plastics and waste rubber into oil and gas by using chemical pyrolysis principle.

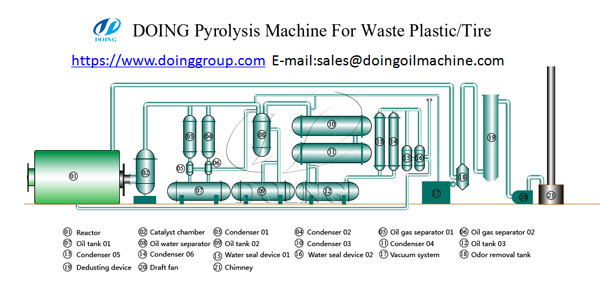

The whole tire pyrolysis process plant is formed by 13 parts, including reactor ,driving device ,vertical catalytic chamber, vertical condenser, oil and water separator, horizontal condenser, oil tank, water seal device, vacuum system, dedusting device, draft fan, chimney.

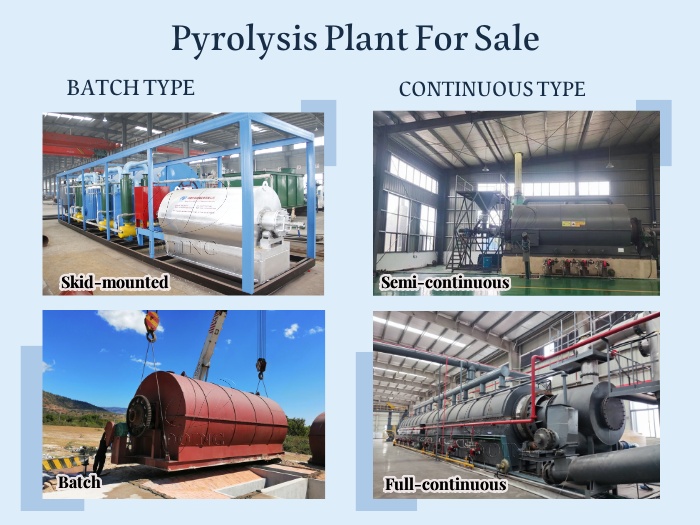

Four types of tire pyrolysis process plant for sale

Four types of tire pyrolysis process plant for sale

The main working processes of tire pyrolysis process plant are as follows:

1. Put the waste tires into the reactor. Don't get too wet as a waste tyre for raw materials. Otherwise, steam will be vaporized before the reactor reaches 100 degrees, which will affect the purity of the collected oil and gas. When the reactor temperature reaches 280 degrees, the tire begins to crack, and the oil and gas production begins, and the effect is best between 280 and 320.

2. The oil gas produced by the tire pyrolysis process plant flow through the catalytic chamber slowly, which will make them fully cooling. Due to the oil and gas in the catalytic chamber is from bottom to top, heavy oil will settle to the bottom after touching the wall, further improving the purity of the oil and gas. After all the pyrolysis process finished ,we should clear oil residueat at the bottom of catalytic chamber.

3. The oil and gas flow through the vertical condenser, which is then stored in the oil tank after cooled. There is a large amount of oil and gas, and the vertical condenser will produce natural negative pressure, which will reduce the pressure on the reactor and will not be easily blocked .After that, the uncooled oil and gas are further separated from the oil and gas separator. The remaining oil and gas passes through the second condenser, the third condenser, to ensure that the oil and gas are fully cooled and the oil yield is the largest. The second condenser is a horizontal condenser, whose cooling area is larger than the vertical one.

4. After these three condensers, the oil gas are basically completely condensed, and the residual is non-condensable gas. Water seal is one of the most important safety device.It can prevent tempering, but also can judge of the cooling system, if cooling is not complete, there will be oil in the the water seal device.

5. Part of the tail gas produced by the tire pyrolysiprocess plant is used to heat the reactor, and some of it is diverted into the air to burn. The DOING's tirepyrolysis process plant is also equipped with a odor removal tank, so the exhaust in the air is tasteless and pollution-free.6. After the tire pyrolysis process ends ,the carbon black is automatically discharged from the side of the reactor.

The main working processes of tire pyrolysis process plant

The main working processes of tire pyrolysis process plant

How to improve the oil production rate of tire pyrolysis process plant:

1. The raw material. Different material have different oil yield. For example ,the oil yield rate of big car tires is about 45% to 52%, while the pure PE plastics is 95%,and unclassified rubbers is approximately 35%.

2. Whether the oil in the material has been completely vaporized. So pay attention to choose professional manufacturers who can supply high quality waste tire pyrolysis process plant with mature pyrolysis technology.

3. Whether oil gas are cooled completely. DOING tire pyrolysis process plant is equipped with professional industrial condensors, which can guarantee the high tire pyrolysis oil yield.

How to improve the oil production rate?

How to improve the oil production rate?

DOING tire pyrolysis process plant can completely evaporate out of oil gas in the raw materials, and the design of three condensers can guarantee that pyrolysis oil could be cooled thoroughly. Therefore, with the same raw material, DOING tire pyrolysis process plant yield more oil than other similar equipments. And for different customers, we can customize suitable scale skid mounted, batch, or fully continuous type waste tire pyrolysis process plant based on the real situation.

For more information about Tire Pyrolysis Process Plant please kindly leave your requirments and your contact information. Our professional project manager will contact you within 24 hours.