Tel/WhatsApp

Tel/WhatsApp

Regular maintenance of waste tire plastic pyrolysis plant is conducive to prolonging the service life of the entire machine. The regular maintenance methods of waste tire plastic pyrolysis plant suggested by Henan Dongying Company are as follows:

DOING factory waste plastics/tyres pyrolysis plant

DOING factory waste plastics/tyres pyrolysis plant

1. Pipeline dredging: Regularly overhaul the waste tire plastic pyrolysis plant, dredge the oil and gas pipelines and condenser pipelines, and keep the oil passages clean and smooth.

2. Circuit maintenance: Check the circuit regularly to ensure that the electrical wiring is firm, and all circuit connections should be operated by qualified engineers.

3. Coking cleaning: During the production process, the furnace wall of waste tire plastic pyrolysis plant reactor. If it is more than 5mm thick, it must be cleaned in time, otherwise once the heat insulation layer is formed, the heating speed will be affected and the oil yield may be reduced.

Daily maintence of pyrolysis machine

Daily maintence of pyrolysis machine

4. Filter screen cleaning: After each production, before feeding raw materials like waste tires and plastics, you must check whether the filter screen at the oil gas outlet is blocked by carbon black agglomerates. If so, you must clean up the carbon black rubber blocks before the next pyrolysis production process.

5. Parts lubrication: Regularly check whether the tugboat, bearings, and gears are running normally, and add lubricating oil in time; because the parts will be heated during operation, adding lubricating oil can reduce their wear and prolong the service life of the equipment.

■Suggestion: Tugboats and bearings can be refilled once a week, and lithium-based grease with a resistance of 800-1000 ° C should be used; during the operation of the waste tire refining equipment, once the tugboat is found to be dry, it must be lubricated; the engine should be lubricated at regular intervals. The reducer is lubricated once with gear oil to ensure that the bearings are lubricated, usually one year.

6. Thickness inspection: The main pyrolysis reactor furnace of waste tire plastic pyrolysis plant is in a high temperature and corrosion state during use, the customer must regularly check and measure the thickness of the steel plate every month after half a year of use, and make a record;

■ Suggestion: If the thickness of the steel plate is less than 6mm, the production should be stopped and the manufacturer of the waste tire plastic pyrolysis plant should be contacted.

DOING waste tyres/plastics pyrolysis plant details

DOING waste tyres/plastics pyrolysis plant details

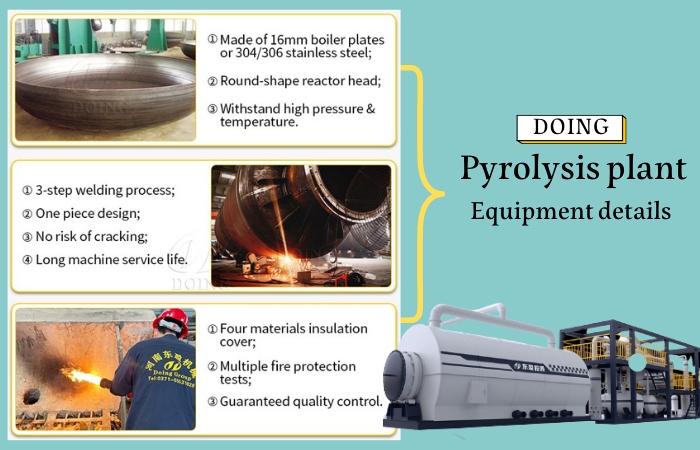

The main furnace of DOING waste tire plastic pyrolysis plant reactor is made according to the production standard of pressure vessel. It is made of boiler plate Angang Q345R/Q245R with a thickness of 16mm/18mm. It can withstand high temperature and high pressure, and has good corrosion resistance. And we also support customizing the full stainless steel pyrolysis reactor.

In terms of welding process, DOING uses 60-degree grooves on both sides of the steel plate to prefabricate the welding grooves, and then uses automatic submerged arc welding technology for double-sided welding to ensure that the waste tire plastic pyrolysis plant will not be desoldered under high temperature heating.

Any mechanical equipment will inevitably have friction loss during long-term operation, and waste tire plastic pyrolysis plant is no exception. Therefore, regular maintenance of pyrolysis plant is essential. Since the pyrolysis plant is a pressure vessel, professional knowledge and skills are required for better operation and maintenance.

Henan Doing Company offers all-around technical support from the waste tire plastic pyrolysis plant selection, fabrication, to technical training on equipment installation, operation and maintenance.

For more information about Regular maintenance of waste tire plastic pyrolysis plant please kindly leave your requirments and your contact information. Our professional project manager will contact you within 24 hours.