Tel/WhatsApp

Tel/WhatsApp

DOING semi-continuous pyrolysis system is a sophisticated piece of machinery designed for the efficient conversion of the waste such as waste tires, plastics, oil sludge and other waste materials into valuable products like oil, carbon black, and syngas. This system bridges the gap between batch pyrolysis system and fully continuous pyrolysis system, offering enhanced efficiency and throughput suitable for medium to large-scale operations.

DOING semi continuous pyrolysis system

DOING semi continuous pyrolysis system

I will introduce you some information about semi-continuous pyrolysis system from the process, product application, advantages and the other aspects.

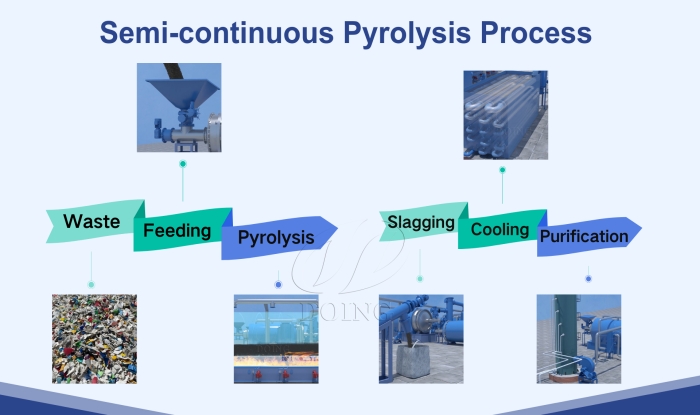

Process of semi-continuous pyrolysis system:

1.Feeding: Loading the rubber powder or plastic particles or oil sludge using a conveyor screw.

2.Pyrolysis: Heating the raw material in the reactor. As the temperature increases to 280-320°, the raw materials are converted to fuel oil, carbon black and syngas.

3.Cooling: Passing through multiple layers of condenser tubes, the oil and gas produced will be fully cooled to ensure 100% oil and gas recovery rate.

4.Carbon black discharge: After the pyrolysis is completed, the obtained carbon black product does not need to be cooled, and the carbon black can be directly discharged to the cooling reactor.

5.Tail gas purification: The pungent odor generated during the pyrolysis process is purified by the gas purification system to meet the emission standards.

Process of semi continuous pyrolysis system

Process of semi continuous pyrolysis system

The product application of semi-continuous pyrolysis system:

After the above process, these generated products fuel oil, carbon black and syngas could be applied in many areas.

1.Fuel oil: Mainly used in iron and steel plants, glass plants, boiler heating, heavy oil generators, and cement plants.

2.Carbon black: It is mainly used for pressure ball combustion and refined milling. Refined flour can be used for new tyres, rubber soles, and pigments.

3.Syngas: Non-condensable gas can be used as fuel to heat the reactor.

The usage of semi continuous pyrolysis system

The usage of semi continuous pyrolysis system

Advantage of semi-continuous pyrolysis system:

1.Higher efficiency: The semi-continuous pyrolysis system could achieve continuous feeding and discharging of materials using conveyor screw which significantly increasing daily processing capacity compared to batch type pyrolysis systems. And semi-continuous pyrolysis system can discharge slag at high temperature that reduces cooling time.

2.More environmentally friendly: Using sealed feeding and discharging technology, the equipment production site is clean and environmentally friendly. DOING can configure environmental protection equipment like exhaust gas cleaning treatment plant, flue gas purification treatment equipment, etc. according to local environmental protection policies to ensure that local environmental protection emission standards are met.

3.High degree of automation: Equipped with a PLC automated control panel, it can monitor and control key parameters such as temperature, pressure and material flow. Real-time monitoring and remote control functions can ensure operational efficiency and safety.

4.High energy efficiency: The combustible tail gas generated during the pyrolysis process can be used as fuel to heat the reactor, reducing external energy requirements.

Energy-saving device of semi-continuous pyrolysis system

Energy-saving device of semi-continuous pyrolysis system

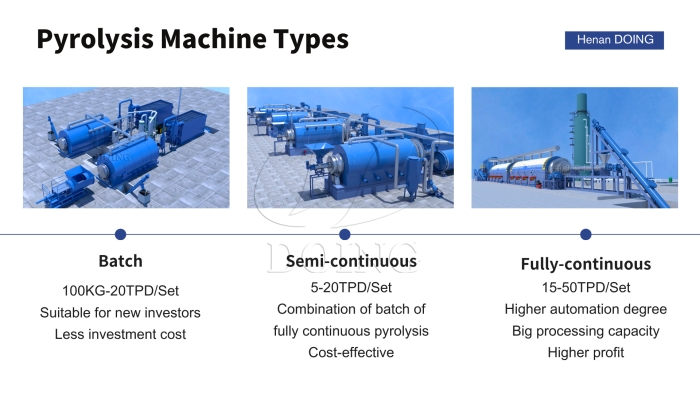

Comparison between semi-continuous pyrolysis system and other types of pyrolysis system

Semi-continuous waste pyrolysis system combine advantages of batch and continuous processes, on the one hand, it feeds raw material and discharges carbon black continuously, which is more efficient than batch type pyrolysis system, on the other hand, it is cheaper than fully continuous pyrolysis system.

Therefore more and more customers are willing to set up a semi-continuous pyrolysis system to make huge profits.

DOING pyrolysis system

DOING pyrolysis system

DOING has exported pyrolysis machines in more than 90 countries and regions, such as the USA, India, Malaysia, Philippines, Iran, France, Spain, Italy, Kenya, Egypt, and has won praise and trust from all over the world. We have many successful cases, this is one of them, for your reference.

If you want to purchase a semi-continuous pyrolysis system, DOING is a good choice for you, all department work together surely to provide you with one-stop high quality service from inquiry, design, production sales and after sales.Welcome to contact us.

For more information about Semi-continuous pyrolysis system introduction please kindly leave your requirments and your contact information. Our professional project manager will contact you within 24 hours.