Tel/WhatsApp

Tel/WhatsApp

In a world grappling with escalating waste management challenges and soaring energy demands, the Refuse Derived Fuel (RDF) Production System emerges as an innovation waste to energy regeneration machine. This RDF production system ingeniously converts diverse waste materials into a valuable energy resource by pyrolysis technology, offering a sustainable and cost-efficient alternative to conventional fossil fuels.

Refuse derived fuel production plant

Refuse derived fuel production plant

What is Refuse Derived Fuel (RDF)?

Refuse Derived Fuel, or RDF, is a fuel derived from solid hazardous waste materials such as rubber materials, used tires, scrap plastics, oil sludge, etc. The production process involves waste materials pretreatment, feeding, thermal cracking, pyrolysis oil condensation, etc. to create a uniform fuel product.

Refuse derived fuel extracted from waste

Refuse derived fuel extracted from waste

How the RDF Production System Operates?

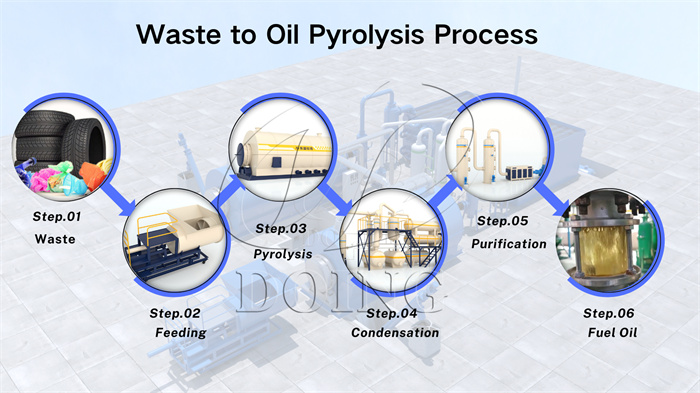

The RDF production process comprises several key stages:

RDF refuse derived fuel production process

RDF refuse derived fuel production process

1. Pre-Treatment of Waste

Sorting: The first step involves sorting the waste to separate combustible materials (like plastics, rubber tires, and organic waste) from non-combustibles (such as metals and glass). This can be done using manual labor, mechanical separators, and automated systems. In addition, continuous RDF production system has requirements for the sizes of the raw materials, it may need the raw material shredding machine.

2. Feeding

Feed the raw materials into the pyrolysis reactor of RDF production system. Different sizes and states of waste raw materials may need different feeders.

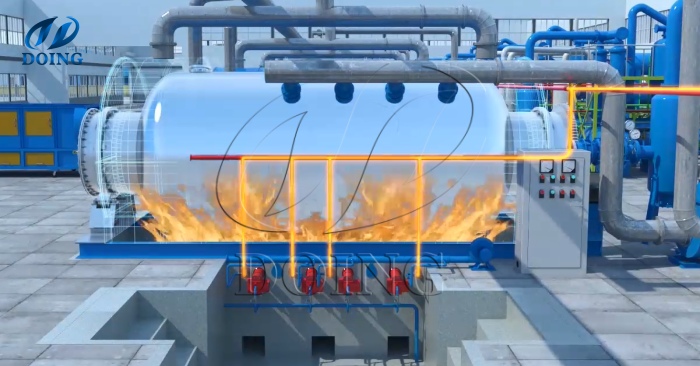

3. Pyrolysis Process

Heating the pyrolysis reactor and the thermal cracking process starts. Oil gas will be extracted from organic waste materials.

Waste thermal pyrolysis process

Waste thermal pyrolysis process

4. Pyrolysis Oil Cooling

The oil gas will go through the industrial condensors for condensation, then the liquid fuel(Refuse Derived Fuel) will be collected in the oil tank. And the solid products will be discharged, the recovered syn-gas will be used for heating pyrolysis reactor, saving energy and pyrolysis system operation cost.

The Advantages of the RDF Production System

The RDF production system offers numerous benefits, including but not limited to:

1. Reduced Landfill Waste: By converting waste into fuel, the system dramatically decreases the volume of waste sent to landfills.

2. Lower Carbon Emissions: The production and use of RDF result in lower carbon emissions compared to traditional fossil fuels.

3. Economic Benefits: The system provides a cost-effective solution for waste management and energy production, creating new revenue streams for businesses. Take waste tire to tire derived fuel production system as an example, a set of 10ton machine can obtain about 1800USD per day.

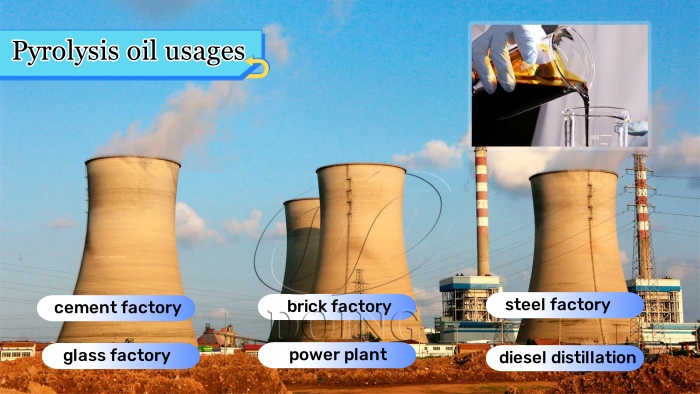

Applications of RDF

RDF can be utilized in various applications, including power generation, cement/glass/china/steel/brick production, and industrial heating. By transforming waste into energy, RDF significantly reduces landfill waste and lowers carbon emissions, contributing to a more sustainable future.

Refuse derived fuel RDF applications and usages

Refuse derived fuel RDF applications and usages

Power Generation: RDF can be burned in heavy oil power plants to generate electricity, providing a sustainable alternative to fossil fuels.

Cement/glass/china/steel Smelting and Production: Cement kilns use RDF as a substitute fuel, reducing production costs and carbon emissions.

Industrial Fuel: RDF is gaining popularity as an industrial fuel, powering boilers and processes in manufacturing and processing industries.

Why Opt for DOING RDF Production System?

Our RDF production system is engineered to meet the highest standards of efficiency and sustainability. With cutting-edge technology and a focus on quality, our system ensures optimal performance and long-term reliability. Our RDF production system can help you achieve your environmental and economic objectives. Till now, we have successful export experience and installation projects of RDF Production System in 100+ countries and regions. We offer all around technical support to help you install the RDF production system smoothly.

RDF production plant operation site

RDF production plant operation site

If you are interested in learning more about our RDF production system or would like to request a consultation, please contact us today. Our team of experts is ready to assist you and provide customized solutions to meet your specific needs.

For more information about Refuse Derived Fuel (RDF) Production System please kindly leave your requirments and your contact information. Our professional project manager will contact you within 24 hours.