Tel/WhatsApp

Tel/WhatsApp

In the rapidly developing world economy, oil resources are becoming increasingly important in our daily lives. As a result, the search for new energy sources has become a priority in many countries. While pyrolysis oil can be obtained from waste tires, rubber, or plastic using a waste tire pyrolysis plant, there is a growing demand for higher quality oils such as diesel.

DOING pyrolysis oil distillation plant 3D picture

DOING pyrolysis oil distillation plant 3D picture

Consequently, the pyrolysis oil distillation plant has emerged as a highly profitable and environmentally friendly project, with low costs, easy access to raw materials, and efficient conversion of pyrolysis oil to diesel or gasoline (with an oil recovery rate of approximately 80-90%).

The complete pyrolysis oil distillation plant involves four main steps:

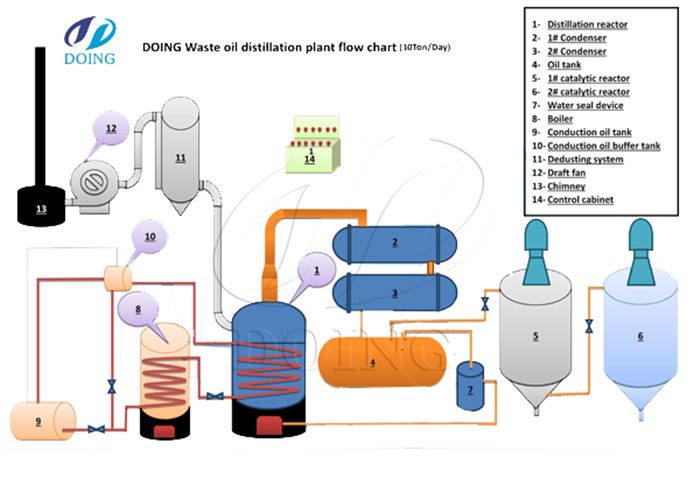

Pyrolysis oil distillation plant working process flow

Pyrolysis oil distillation plant working process flow

1. Firstly, if your waste oil raw material contains a lot of impurities, it suggests to filter the waste oils by the precipitation tank through the oil pipe.

2. After 3 hours, the sediment in the raw material precipitation tank is discharged, and the precipitated crude oil is transferred to the distillation tower via the oil pipe.

3. The distillation process begins with high-temperature heating using fuel oil to heat the distillation reactor. The raw material is heated between the oil heating furnace and distillation reactor, and when the desired temperature is reached, the oil gas from each reactor enters the heat exchange system and condenser system through the distillation tower.

4. Then we can further refine the distilled pyrolysis oil by acid and alkali washing way. You can also choose to decolorize the fuel oil to obtain bright color diesel. Then the final product, diesel, will be stored in separate oil tanks. And the asphalt will be discharged smoothly from the pyrolysis oil distillation plant's vertical reactor.

Noted: We Henan Doing Company also designed the solid catalysts technology pyrolysis oil distillation plant, which has higher efficiency and higher automation degree. Relatively, the cost is higher than the liquid catalyst technology pyrolysis oil distillation plant.

Liquid solid catalysts pyrolysis oil distillation plants comparisons

Liquid solid catalysts pyrolysis oil distillation plants comparisons

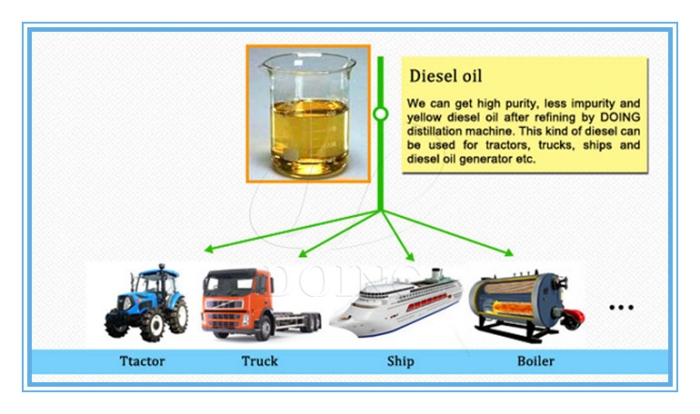

5. Once processed by the pyrolysis oil distillation plant, various types of pyrolysis oil or waste oil/crude oil like used engine motor oil, black oil, old lubricant oil, etc. can be transformed into diesel, increasing their market value and expanding their applications. This makes it the best choice for buyers of pyrolysis oil to further process the oil. The final diesel is a high-value alternative fuel that can be used in diesel generator sets, heavy machinery like tractors, trucks, ships, boats, etc.

Pyrolysis oil distillation plant final product diesel fuel application

Pyrolysis oil distillation plant final product diesel fuel application

Advantages of Pyrolysis Oil Distillation Plant:

1. High production yield: The raw material recovery ratio is approximately 80-90%, and can even exceed 90% when the water content is less than 5%.

2. High on-stream efficiency without corrosion, fouling, and coking.

3. Auto feeding and slag discharging enable continuous operation throughout the day.

4. Environmental friendly operation technology and devices ensure no soil, water, or air pollution.

5. Cost-effective oil refining to diesel technology.

6. Easy to clean and maintain due to its vertical structure.

7. Provides an alternative energy source to replace petroleum products and natural gas.

Pyrolysis oil distillation plant final fuel installed by DOING

Pyrolysis oil distillation plant final fuel installed by DOING

The common capacity of DOING pyrolysis oil distillation plant is about 100kg to 14 tons per day per set. We Henan Doing Company offer different scales of machine solutions and have a professional engineer team to customize bigger scale of solutions. Welcome to leave your inquiry and our sales manager will contact you within 24 hours to negotiate the details with you.

For more information about DOING Pyrolysis oil distillation plant please kindly leave your requirments and your contact information. Our professional project manager will contact you within 24 hours.