Tel/WhatsApp

Tel/WhatsApp

Nowadays, how to convert tyre/plastic into pyrolysis oil is no longer a problem .By using the pyrolysis plant, we can get pyrolysis oil from waste tire plastic. Secondly, with the help of pyrolysis oil refining process plant , the pyrolysis oil can be further refined into diesel oil that fetch a better price than pyrolysis oil on the market. Besides, pyrolysis oil refining process plant can also transform other crude oil into diesel and asphalt, such as plastic/rubber pyrolysis oil , waste engine motor oil generated from vihicles and ships, heavy oil, mazut, old lube oil, etc.

Pyrolysis oil refining process plant project picture

Pyrolysis oil refining process plant project picture

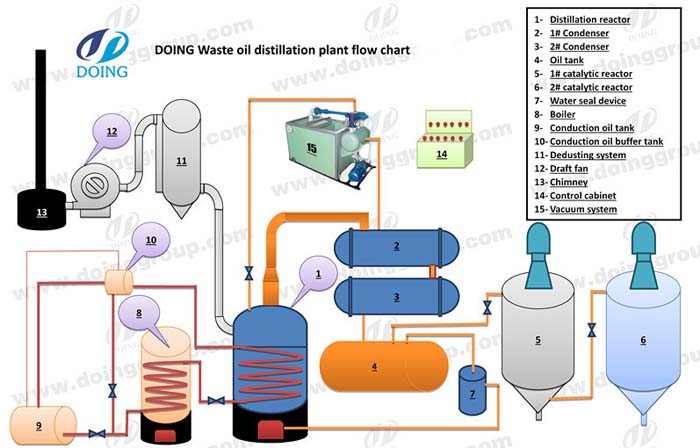

Pyrolysis oil refining process plant use the theory of distillation, a green technology. The whole refining process includes distillation, cooling, decoloring and deodoring system. Pyrolysis oil refining process plant include many parts : distillation reactor, condenser, oil tank, catalytic reactor, water seal device, boiler, conduction oil tank, conduction oil buffer tank, dedusting system, draft fan, chimney, control cabinet, vacuum system.

Pyrolysis oil refining process plant working process

Pyrolysis oil refining process plant working process

Pyrolysis oil refining process plant working process :

1. Prepare crude oil

Pump the crude oil/waste tire plastic pyrolysis oil in the reactor oil pyrolysis oil refining plant for further process;

2. Heating for distillation

Heat pyrolysis oil in non-oxygen environment, which will start to boil and evaporate; at the same time, heat conduction oil also transfer heat to crude, so the temperature goes up very quickly.

3. Cooling

Put those vapors through a cooling pipe and the vapors will condense to liquid, while some of the vapors with shorter hydrocarbon lengths will remain as a gas.

4. Chemical process for cleaning the distillation oil

The exit of the cooling pipe is then going through a bubbler containing water to capture the last liquid forms of fuel and leave only gas that is then burned in the reactor; the extracted fuel oil will be mixed with acid-alkali luquids. This kind of diesel oil will be piped into deep purifying system with acidity and alkaline cleaning device as well as pressure filtering system.

5. Collect final diesel product

The color of the diesel directly produced from the standard pyrolysis oil refining process plant is brown yellow. The purification system could make further purification for the diesel ,thus to get light yellow color. And right now we also design the new design solid catalyst pyrolysis oil refining process plant, which is more convenient, easy-handing, energy&labor saving.

Note: Above pyrolysis oil to diesel refining process is just one of the common process designed by Henan Doing Company. Besides that, we also have the new design pyrolysis oil refining process plant, which uses the solid catalyst instead of yrolysis oil, with higher efficiency.

Two types of pyrolysis oil refining process plant for sale

Two types of pyrolysis oil refining process plant for sale

Advantages of pyrolysis oil refining process plant:

1. Fast heating system

All the system is sealed,so the loss of heat is less. Conduction oil is for recycling use, which can save a lot of heating fuel for you. No smell and smoke produce, so there is no harm to the workers. conduction oil doesn’t heat reactor directly, and it is helpful to prolong the life of the reactor. Coil heater can make heating evenly and fast. Combined with indirect heating system ,the reactor can keep hot for longer time, so the whole process is faster with less fuel.

Advantages of DOING pyrolysis oil refining process plant

Advantages of DOING pyrolysis oil refining process plant

2. Vertical design

From our design, It is very easy to clean the slag , asphalt residues will be discharged from the bottom of the vertical reactors automaticly.

3. Continuously working

When operating the machine, first you pump oil inside the reactor to heat;after finishing heating, it will become oil gas and goes to cooling system, then goes to oil tank. So, the first reactor is empty, no need to stop, you could pump another tank of crude oil again into the first tank ,continuously working.

4. High purity

The oil recovery rate is about 85%. The diesel oil or gasoline we finally get from this plant has clean , transparent color and qualified smell , which can be widely applied in tractors, trucks, generators, boilers, agricultural vehicles etc. and will produce less smoke and less noise than regular diesel fuel.

5. Diesel further purification system

What liquefied from the condenser is the nonstandard diesel oil of brown and yellow. After being further deodorized and decolored in diesel further purification system , we can get high purity and and light yellow diesel oil.

Diesel oil applicationProducts of pyrolysis oil refining plant and application:

Diesel oil applicationProducts of pyrolysis oil refining plant and application:

Products of pyrolysis oil refining plant include 85% diesel, 10% asphalt, 5% water and other impurities. The final diesel after refining can be used for tractors, trucks, ships and diesel oil generators etc, and asphalt usually for paving and refinery.

We Henan Doing Company supplies different capacities and different catalyst designs of pyrolysis oil refining process plants for sale. If you want to further refine tire plastic pyrolysis oil to get high quality diesel, please contact us.

For more information about Pyrolysis oil refining process plant please kindly leave your requirments and your contact information. Our professional project manager will contact you within 24 hours.