Tel/WhatsApp

Tel/WhatsApp

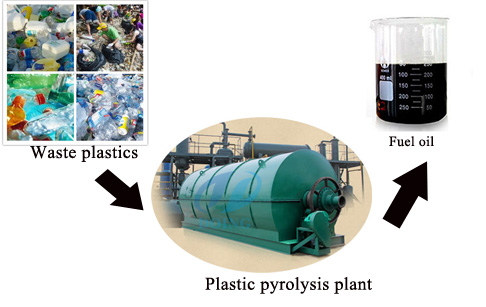

Waste plastic to oil pyrolysis plant

Waste plastic to oil pyrolysis plant adopts the most advanced technology in the world which is called pyrolysis. Through this technology, you can use waste plastics as raw materials and finally you will get qualified plastic oil and carbon black. For example, the plastic oil can be widely used as fuel oil in industries such as steel, iron and boiler factories, ceramics, power or chemical industries or hotels, restaurants etc. or used for generators to get electricity. The carbon black can be used for making construction bricks with clay. Even the gas can be recycled to heat the reactor as fuel, which will save energy for the whole recycling process of plastic.

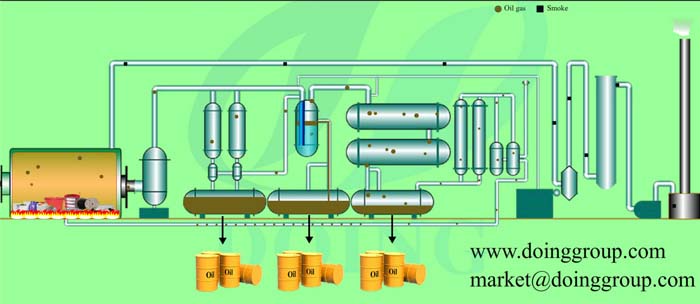

Wate plastic to oil pyrolysis plant working process

Waste plastic to oil pyrolysis plan is processing waste plastic

1. Put raw materials into reactor by auto-feeder, then heat the reactor with any one of the following fuel materials: coal, wood, natural gas, oil. Do not stop heating the reactor, when the temperature reaches nearly 250 degree Celsius, waste tyre will be transferred to oil gas.

2. The liquid oil will be cooled by condenser from oil gas and then collected by oil tank. Third, the exhaust gas which can not be cooled in normal pressure will be recycled to heat the reactor. In this way, you can not only saving energy, but also protecting environment.

3. Smoke produced by processing the tyres/plastics can achieve national emission standard through dual desulfurization and dusting removal device.

4. After you get oil, the temperature will be low, at this time, carbon black will be discharged automatically.

Last, when the temperature falls to 100 degree Celsius, worker could put steel wire hook to reactor to take steel wire out. After all these steps, you can start another batch.

Wate plastic to oil pyrolysis plant tech data

| Technical parameter of waste plastic to oil pyrolysis plant | ||||

| No. | Items | Contents | ||

| 1 | Equipment type | DY-1-6 | DY-1-8 | DY-1-10 |

| 2 | Raw material | Waste plastic | Waste plastic | Waste plastic |

| 3 | Structural form | Horizontal rotation | Horizontal rotation | Horizontal rotation |

| 4 | 24-hour Capacity | 6 ton | 8 ton | 10 ton |

| 5 | Oil yield | 2.7-3.3ton | 3.6 -4.4ton | 4.5 -5.5ton |

| 6 | Operating pressure | Normal | Normal | Normal |

| 7 | Material of pyrolysis Reactor | Q245R | Q245R | Q245R |

| 8 | Thickness of pyrolysis Reactor | 16mm | 16mm | 16mm |

| 9 | Rotate speed of pyrolysis Reactor | 0.4turn/minute | 0.4turn/minute | 0.4turn/minute |

| 10 | Total power | 19KW | 19KW | 19KW |

| 11 | Mode of cooling | Water cooling | Water cooling | Water cooling |

| 12 | Cooling area of condenser | 100sqm | 100sqm | 100sqm |

| 13 | Kind of transmission | Internal gear drive | Internal gear drive | Internal gear drive |

| 14 | Noise dB(A) | ≤85 | ≤85 | ≤85 |

| 15 | Size of Reactor(D×L) | 2200×6000 | 2200×6600 | 2600×6600 |

| 16 | Working form | Intermittent operation | Intermittent operation | Intermittent operation |

| 17 | Delivery time | 20days | 20days | 20days |

| 18 | Weight | 27T | 30T | 35T |

| Prepared by customer about automatic waste plastic to oil pyrolysis plant | |||

| No. | Item | Consumption | |

| 1 | Coal(for choice) | 500kg/day | |

| 2 | Wood(for choice) | 800kg/day | |

| 3 | Natural gas(for choice) | 100-150kg/day | |

| 4 | Oil(for choice) | 300-350kg/day | |

| 5 | Electricity | 244kwh/day | |

| 6 | Water(recycled) | 60? /month | |

| 7 | Total power | 19kw | |

| 8 | Land area | 35m*15m | |

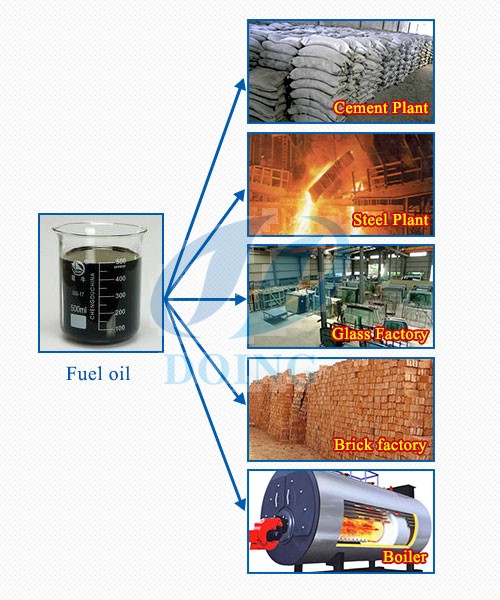

Wate plastic to oil pyrolysis plant final product application

1.Fuel Oil (40% to 45%)

The main application of oil products produced by our waste tyre oil extraction machine is the fuel oil that is wide used for industrial and commercial purposes. Such as power plant factory,glass factory,cement factory,ceramic fatory.

Carbon black application

Carbon black (30%): First, Carbon black from waste plastic to oil pyrolysis plant is crude oil. You can sell it to the brick factory as internal combustion or to the factory which need it as raw materials, such as shoe, tire, cable and sealant companies. Second, could make further process, make carbon black powder into carbon black briquette, and use it for burning.

2.Exhaust gas (About 10%)

We get about 10% pyrolytic gases during pyrolysis process. The main component of this gases are methane (CH4), so we can not condense and store this gases. We use this gases to heat the reactor and we can use exceed gases for other heating application.

For more information about Wate plastic to oil pyrolysis plant please kindly leave your requirments and your contact information. Our professional project manager will contact you within 24 hours.